Trends in Fuel System Component Coating Technologies

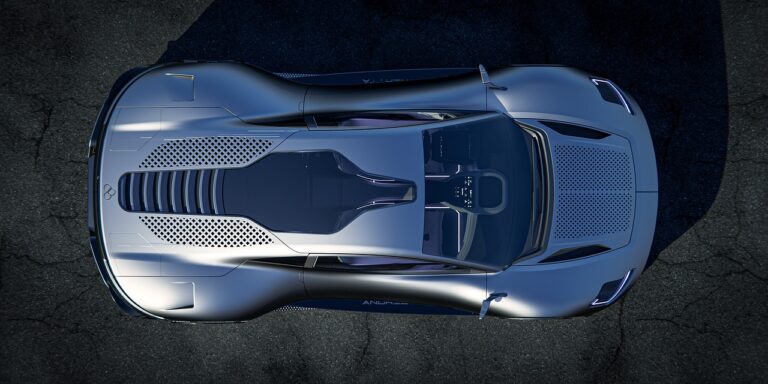

allexchbet, 99exch, all panel.com:Fuel system component coating technologies have been advancing rapidly in recent years, leading to significant improvements in efficiency, performance, and durability. These coatings play a crucial role in protecting fuel system components from wear, corrosion, and other forms of damage, ultimately extending their lifespan and enhancing overall system reliability. In this article, we will take a closer look at some of the key trends in fuel system component coating technologies that are shaping the industry today.

The importance of fuel system component coatings cannot be overstated in today’s automotive landscape. The advent of more stringent emissions regulations, the rise of alternative fuel sources, and the constant drive for improved efficiency have all placed greater demands on fuel system components. Coatings help to address these challenges by providing a layer of protection that helps components withstand the harsh operating conditions they are exposed to.

One of the key trends in fuel system component coating technologies is the use of advanced materials. Traditional coatings such as chrome plating and anodizing are being replaced by newer, more advanced materials that offer superior performance and durability. For example, thermal spray coatings, such as high-velocity oxygen fuel (HVOF) coatings, are becoming increasingly popular due to their excellent wear resistance and thermal stability.

Another trend in fuel system component coating technologies is the development of multifunctional coatings. These coatings not only provide protection against wear and corrosion but also offer additional functionalities such as thermal insulation, lubrication, and even self-healing capabilities. By incorporating multiple functionalities into a single coating, manufacturers can achieve greater efficiency and performance in their fuel system components.

Nanotechnology is also making a significant impact on fuel system component coating technologies. Nanocoatings, which are composed of nano-sized particles, offer enhanced performance due to their unique properties. These coatings can provide improved adhesion, increased hardness, and better chemical resistance compared to traditional coatings. Nanotechnology is enabling the development of next-generation fuel system components that are lighter, stronger, and more efficient than ever before.

In addition to advancements in materials and technology, the application process for fuel system component coatings is also evolving. Manufacturers are increasingly turning to advanced coating techniques such as plasma spraying, chemical vapor deposition (CVD), and physical vapor deposition (PVD) to achieve precise, uniform coatings with minimal waste. These techniques offer greater control over the coating thickness, composition, and structure, resulting in coatings that are tailored to meet specific performance requirements.

Overall, the future of fuel system component coating technologies looks bright, with continued advancements in materials, technology, and application processes driving innovation in the industry. By embracing these trends and adopting the latest coating technologies, manufacturers can stay ahead of the curve and provide their customers with fuel system components that deliver exceptional performance, durability, and reliability.

FAQs:

Q: Are fuel system component coatings really necessary?

A: Yes, fuel system component coatings are essential for protecting components from wear, corrosion, and other forms of damage, ultimately extending their lifespan and improving system reliability.

Q: What are some common types of fuel system component coatings?

A: Some common types of fuel system component coatings include thermal spray coatings, nanocoatings, and multifunctional coatings.

Q: How can manufacturers benefit from advanced fuel system component coatings?

A: Manufacturers can benefit from advanced fuel system component coatings by improving the performance, efficiency, and durability of their components, ultimately gaining a competitive edge in the market.

Q: What is the future outlook for fuel system component coating technologies?

A: The future looks promising for fuel system component coating technologies, with ongoing advancements in materials, technology, and application processes driving innovation in the industry.